Factors Influencing Siding Installation Labor Cost

Exploring the realm of siding installation labor costs, this article delves into the key factors shaping the expenses involved. From materials to regional variations, discover what drives the overall cost of labor in this intricate process.

As we journey through the nuances of siding installation labor costs, we uncover the various components that contribute to the final bill, shedding light on strategies to optimize expenses without compromising quality.

Factors Affecting Siding Installation Labor Cost

When determining the labor cost for siding installation, several key factors come into play. Understanding these factors can help homeowners budget effectively for their siding project. Let's explore how each factor influences the overall labor cost.

1. Type of Siding Material

The type of siding material chosen significantly impacts the labor cost. For example, vinyl siding is generally easier and quicker to install compared to wood siding, which may require more time and expertise. The complexity of working with certain materials can result in higher labor costs.

2. Siding Design and Layout

The design and layout of the siding also play a crucial role in determining labor costs. Intricate designs or patterns may require more time and precision to install, leading to higher labor expenses. Additionally, multi-story homes or structures with unique architectural features can increase the complexity of the installation process.

3. Size of the Project

The size of the siding installation project directly affects labor costs. Larger projects that require more materials and manpower will naturally incur higher labor expenses. Conversely, smaller projects may be more cost-effective in terms of labor.

4. Accessibility and Site Conditions

The accessibility of the work site and existing site conditions can impact labor costs. Difficult-to-reach areas, uneven terrain, or the need for specialized equipment can all contribute to increased labor expenses. Contractors may need to spend more time and effort overcoming site challenges, leading to higher costs.

5. Labor Rates and Experience

Labor rates set by the contractor and the experience level of the installation crew are essential factors in determining labor costs. Highly skilled and experienced laborers may charge higher rates for their expertise, while less experienced workers may offer more affordable pricing.

The quality of workmanship and efficiency of the crew can influence overall labor expenses.

6. Seasonal Demand and Timing

Seasonal demand and the timing of the siding installation can also impact labor costs. Contractors may adjust their rates based on peak seasons or availability, leading to fluctuations in labor expenses. Planning the installation during off-peak times or slower seasons may result in more competitive pricing for labor.

Average Cost of Siding Installation Labor

When it comes to the average cost of siding installation labor, it typically ranges from $3 to $10 per square foot. This cost includes the labor required to install the siding material properly on the exterior of a building.

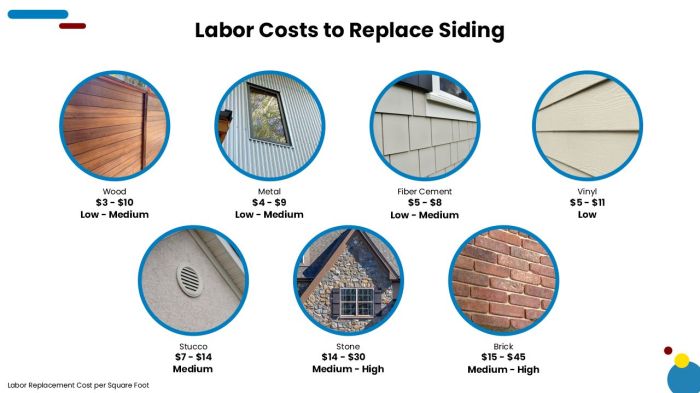

Variations in Labor Costs Based on Siding Material

Different types of siding materials can impact the labor costs of installation. For instance, vinyl siding is generally easier and quicker to install compared to fiber cement siding or natural wood siding

Regional Differences Affecting Labor Costs

Regional differences can also play a significant role in determining the average labor cost for siding installation. In areas with higher costs of living or where labor is in high demand, such as urban areas or regions with strict building codes, the labor cost for siding installation may be higher.

On the other hand, in more rural areas with lower costs of living, the labor cost for siding installation may be lower.

Cost Breakdown of Siding Installation Labor

When looking at the cost breakdown of siding installation labor, it is essential to understand the different components that make up the total labor cost. These components include preparation, installation, and cleanup. Each of these elements plays a crucial role in determining the overall cost of the siding installation project.

Preparation

- Preparation involves tasks such as removing old siding, inspecting the exterior of the house, and making any necessary repairs before the new siding can be installed.

- This stage typically accounts for around 10% to 20% of the total labor cost, depending on the extent of the preparation work required.

Installation

- The installation phase is where the actual siding is put in place, including cutting, fitting, and securing the siding materials to the exterior of the house.

- On average, installation makes up the bulk of the labor cost, contributing approximately 60% to 70% of the total labor expenses.

Cleanup

- Once the siding installation is complete, the cleanup phase involves removing debris, tidying up the work area, and ensuring the exterior of the house looks clean and presentable.

- Cleanup typically represents around 10% to 20% of the total labor cost, depending on the size of the project and the amount of waste generated.

Ways to Reduce Siding Installation Labor Cost

When looking to minimize siding installation labor costs, it's important to consider various strategies that can help you save money without compromising the quality of the work. By implementing efficient practices and making smart decisions, you can effectively reduce labor expenses during the siding installation process.

Optimize Work Schedule

One way to reduce siding installation labor costs is by optimizing the work schedule. This involves planning the project in advance and scheduling tasks in a way that maximizes efficiency. By minimizing downtime and ensuring that workers are utilized effectively, you can reduce the overall labor hours required for the project.

Use Prefabricated Materials

Another cost-saving measure is to use prefabricated siding materials. Prefabricated materials are pre-cut and ready to install, which can significantly reduce the time and labor required for installation. While prefabricated materials may have a higher upfront cost, the time saved during installation can help offset the expenses.

Invest in Training and Skill Development

Investing in training and skill development for your siding installation team can also help reduce labor costs in the long run. Well-trained workers are more efficient and productive, leading to faster installation times and lower overall labor expenses. By improving the skills of your team, you can increase efficiency and reduce the need for additional labor hours.

Concluding Remarks

In conclusion, the intricacies of siding installation labor costs are multifaceted, with each factor playing a crucial role in the final tally. By understanding these elements, homeowners can make informed decisions to enhance their property while managing expenses effectively.

Detailed FAQs

What factors can impact siding installation labor cost?

Factors such as material type, preparation requirements, and regional labor rates can significantly influence siding installation labor costs.

Is there a standard average cost for siding installation labor?

The average labor cost for siding installation typically ranges from $3 to $8 per square foot, varying based on factors like material and location.

How can homeowners reduce siding installation labor costs?

Homeowners can reduce labor costs by opting for cost-effective materials, planning efficiently, and hiring experienced professionals for the job.